News

Ready for action!

On Tuesday the First Phase of the organ installation was finished. We now have all the restored casework, the refurbished display pipes and all of the organ working, apart from the Choir division (the third keyboard), which will be completed when funds allow. Final ‘handover will be in December when we have its final tuning after a ‘bedding in’ period of a couple of months.

On Friday evening, as part of our Earlsdon and Chapelfields Christian Communities’ Arts Festival, ‘How Great Thou Art’ Keith will be demonstrating the organ and its range of tone at 7.45pm Visitors will be able to hear and see what the organ does and see our display of ikons in the Church.

No more organ parts at home!

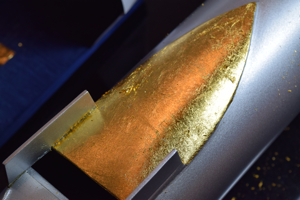

For the first time for a year we have no organ parts being worked on at home – I finished gilding the last of the display parts and took them off to All Souls on Sunday afternoon, where they are now waiting to be installed alongside the centre pipes which I fitted on Saturday.

It’s all working!

Last Sunday we had the organ in full working order for the first time. There is still some fine-tuning and blending to be done and the keyboards will be re-balanced to ensure that the touch is completely even, but we are in action. To celebrate, I played the Dubois Toccata at the end of Mass.

The Dubois Toccata getting an airing with Emily in the mirror (she was page-turning!) and Gabby clearing up music after Mass. Note the mirror (no expense spared – £15 from Homebase) and the state of the art console lights (2 halogen desk lamps bought from Homebase in 2009 and re-engineered by me – saving over £300!).

wesprayanything.com – and they do!

The front display pipes on our old organ are being re-used in the new one. Although they are real organ pipes, they are not connected to the wind and make no sound. They were in a terrible state, with at least 3 thick layers of paint (originally “gold” – then 2 layers of aluminium, all painted by brush, with obvious brush strokes and without the pipes being taken out). After some debate, the only solution was to take out all 27 pipes (some of which are over 10 foot long), strip the paint off by hand, clean them with wire wool and white spirit, and then have them refurbished and painted. Emily and I started taking the pipes out in August last year and I brought them home (some stored in my garage, and some in my mother’s garage!).

Bit by bit I cleaned each pipe (gallons of Nitromors!) and polished it up (that takes over 2 hours per pipe). After various trials, it was obvious that they would be best sprayed silver, with the mouths properly gilded with gold leaf (the traditional way of decorating display pipes). My spraying skills are negligible and I don’t have a spray booth, so I had to get someone to do it. I thought about getting a car bodyshop involved, and then came the Budget! On budget night the BBC local news featured a small paint spraying business in Bromsgrove (“wesprayanything.com”) and looked at how it would be affected by the Chancellor’s latest efforts. We might have found our solution – so I took a couple of pipes down to Bromsgrove. Organ pipes were something new to Paul and his team, but they were not daunted and after an hour or so, we had agreed on a colour and finish. Paul agreed to do a trial pipe and emailed photos of it to me. The colour was perfect, so we decided to try a matt polyurethane finish, but when I went down to see it, it was too dull. We then tried a sheen finish and I was happy – so during July, the pipes were taken down to Bromsgrove in batches of 9 and sprayed before coming back to my house in August for gilding.

Problems with the Mixture

A mixture is an organ stop where more than one pipe sounds for each note. On our organ there is a 3 rank mixture on the Swell division – so 3 pipes speak when each key is pressed. Each rank sounds at a different (and high!) pitch so that a blend of harmonics can be added to the chorus of pipes when stops are drawn.

Our mixture has pipes pitched at seventeenth (i.e. the bottom pipe sounds E above middle C), nineteenth (G above middle C) and twenty-second (C an octave above middle C). As you move up the keyboard, the pipes get smaller and shriller and the sound can get unpleasant (and eventually, if nothing was done, they would be pitched so high that the human ear cannot hear them).

The solution is to have each rank “break back” at different points in the range so that at the point where the rank “breaks” it is re-set with lower pitched pipes, and the pipes start longer and get smaller as they go up. Another trick, in blending the ranks to get the best “silvery” sound from the mixture, is to change the pitching of the rank.

On our mixture, we hit a real problem when it was being voiced. In the section about an octave above middle C, one of the ranks was much too dominant and produced a very shrill, and to my ears unpleasant sound. Mike and Simon eventually concluded that the best “fix” was to replace the offending pipes with slightly wider pipes tuned to the fifteenth, which had the effect of slightly lowering the pitch of that part of the mixture and giving a gentler and more pleasant sound. They used some of the small pipes from our old organ from a stop that was not useable as a complete stop, and then the pipes were cut down so that they sounded at a much higher pitch that used to be the case. Eventually, with skilful tuning and voicing (making minute alterations to the pipes) the whole of the Swell division now blends perfectly.

Events since June Pt2

In late June, when work was being done blending the sound of all the pipes in the swell division (in organ builder speak, “regulating”) we discovered that the bottom pipes of the 16′ Bassoon would not sound promptly or properly. These are the only new pipes on the organ, made specially to match the pipes that had come from St Mary’s Leak. In mid-July David Hall, of pipe-makers Booths, came down from Leeds and spent a day working on the pipes with the team from Thompsons.

It turned out that the pipes had been correctly voiced on the correct wind pressure in the factory, so David then had to try to work out what was wrong. Eventually, the conclusion was that the problem was caused by fluctuations in the wind as it moved through the trunking from the bellows. By a clever combination of making minute alterations inside the pipes and increasing the speed of the magnets by a small increase in the power voltage the pipes eventually made to “speak” perfectly as soon as a key was pressed. David then skilfully re-blended them with the other Bassoon pipes and work could then continue on the rest of the Swell.

Events since June – Pt1

It’s been a little time since I last posted any news. That’s because I normally do this late at night, but since June I have spent every free evening making new corner pieces to insert into the empty corner pieces of the casework that were never completed when the original All Souls organ was built just before World War II.

I decided that it would be nice if we could have some gilded carvings to match the other gilding on the case. After some searching, I found some pilgrim shells carved in limewood and got six of them in the right size. I made six backing plates to fit the gaps in the organ case from thin oak-faced plywood and applied wood dye and button polish to the oak veneer until it matched the oak in the case. I then gilded the shells and glued them to the backing plates and fitted them into the organ case.

Gilding has to be carefully timed, so I tend to prepare the surface and apply gilding size just before dinner in the evening. About three hours later it is ready for the gold leaf to be applied, so I tend to start on that around 10.40pm… and finish when the job is done – usually around 12.30pm. The last pieces were fitted in late July.

The last lap is in sight

This week has seen a lot of progress and final tuning and “regulation”(making sure all the pipes are in tune, and that all stops blend together and sound at their best in the Church’s acoustic) begins next week. Virtually all the pipes are now fitted and speaking and the stop motors for the Great are in place and working. Our organ builders have also worked out why our blower motor from our old organ, which was added relatively recently, has always been so noisy. It looks as if its phasing was crossed when it was originally fitted, causing it to run the fan backwards! Now that this has been fixed, it is much quieter. The bass pipes in the pedal need some adjusting so that their “speech” is prompt, but otherwise, they sound fine, and the main part of the Swell mechanism has been fitted and works well.

Next week, in addition to tuning and regulation, the refurbished pedalboard will be fitted, together with the toe pistons, and the Swell mechanism should be completed. The last significant piece of work in the workshop – the construction of the small wind chest for the Great Tierce should also be done and that will be built into the organ case. The target is to have the organ fully playable by the end of June.

More wind!

We were hoping to have the organ playable for Pentecost, but it was not possible. The big Pedal and Great reed pipes (which are on separate wind chests from the rest of the organ) operate on 6″ wind pressure (the rest of the organ is on 3″). In order to achieve that, there has to be a separate bellows reservoir made and fitted which pushes out wind at 6″. That has taken a little longer to make than expected, but is now fitted, together with all the trunking that will take the wind to the relevant wind chests. This has, however, delayed the completion and fitting of the stop motor unit for the Great. Hopefully this week will see this completed and fitted, so that the whole organ can be connected up and “regulating” can begin.

“Regulating” is the tuning and voicing of all of the pipes so that they sound at their best in the building and all blend with each other in tune, which will probably take just over a week. In the meantime, work has started on making the linkage that will enable the swell box doors to open gradually at the press of a pedal. We will be re-using the mechanism from our old organ, but it will need to be adapted as the console will now face the pipes and be built in to the organ, rather than placed away from the pipes and sideways on, as used to be the case.

Back at home, I have now finished stripping all the old paint from the display pipes, buffed them up with wire wool and washed them, ready for spraying with special paint that looks like polished tin. Once that is done, I apply decorative gold leaf to the months.

While I wait for the pipes to be sprayed I will (i) be working on my garden (which has been badly neglected this year! and (ii) making some wooden inserts for six empty spaces on the front of the organ case, staining and polishing them, then fitting and gilding some decorative mouldings that will complete the casework scheme.

Tuning begins!

All the Swell Organ stop motors have been fitted and are now working, so on Friday most of the Swell stops (everything other than the Cornopean, Celeste, Mixture and Bassoon) had their first rough tuning. They sound a lot brighter than they did in the workshop when the Swell division was first built last October – they are gaining a lot from the superb acoustic in the church. Next week, we should have the Great stop motors in and working, and a few software adjustments are to be made before more of the organ will be playable. In addition the reservoir for the wind for the Great Trumpet and the Pedal Trombone has been made and will be fitted. These stops have a separate reservoir as they will work on 6″ wind pressure, whereas the rest of the organ is on 3″.

Back at home, I now only have 3 of the 27 display pipes waiting to be stripped of all paint and washed down – my target is to finish that task by next weekend as the first batch are being sprayed.